Ramtech Building Systems is a leading provider of modular building systems including relocatable, permanent and prefabricated constructions.

T (817) 473-9376

Email: sale@viennavahouses.com

Ramtech Bulding Systems

1400 US Hwy 287 South Mansfield, TX 76063

Ramtech Blog

Why Modular Buildings Are the Future of Sustainable Construction Solutions

Modular buildings have emerged as a pioneering solution in sustainable construction, transforming the way we approach design and efficiency in the built environment. As the industry grapples with the pressing challenges of climate change and resource conservation, experts are advocating for innovative strategies that prioritize sustainability. One such expert, Dr. Sarah Thompson, a leading authority in modular construction, emphasizes, "Modular buildings not only reduce waste and carbon emissions but also enhance the speed and quality of the construction process."

This forward-thinking approach aligns with the growing demand for environmentally friendly practices within the construction sector. Modular buildings, characterized by their prefabricated components that are fabricated off-site and assembled on location, offer significant advantages in reducing construction time and minimizing material waste. As more architects, developers, and policymakers recognize the multifaceted benefits of modular construction, it becomes increasingly evident that these structures represent a crucial step toward a sustainable future in the industry.

In summary, the integration of modular buildings into modern construction practices is not merely a trend, but a sustainable transformation that promises to revolutionize how we build and occupy spaces. With the focus on efficiency and environmental stewardship, the modular building sector is poised to lead the way in reshaping the landscape of sustainable architecture and urban development.

The Rise of Modular Buildings in Sustainable Construction Trends

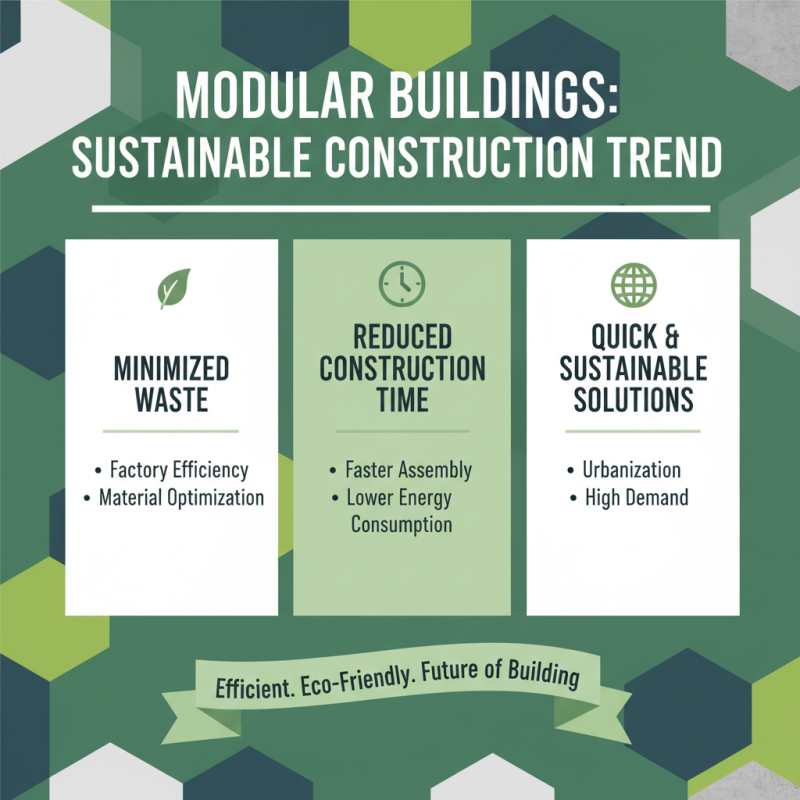

The rise of modular buildings in sustainable construction trends marks a significant shift towards more environmentally friendly and efficient building practices. Modular construction, which involves prefabricating sections of buildings off-site and then assembling them on-site, offers numerous advantages that align with sustainability goals. First and foremost, this method minimizes waste, as materials can be used more efficiently during the factory process. Additionally, construction time is significantly reduced, leading to lower energy consumption during the building phase. As urbanization continues to accelerate, the demand for quick and sustainable solutions has never been higher, making modular buildings an appealing choice for developers and communities alike.

Furthermore, modular buildings are designed with sustainability in mind, often incorporating energy-efficient systems and sustainable materials. This focus on eco-friendly design not only reduces the environmental impact during construction but also contributes to lower operational costs over the building's lifetime. As more architects and engineers recognize the potential of modular construction, there is a growing trend towards integrating innovative technologies, such as solar panels and green roofs, further enhancing the sustainability of these structures. The combination of speed, efficiency, and eco-conscious design positions modular buildings as a leading solution in the evolution of sustainable construction practices.

Key Benefits of Modular Construction: Efficiency and Resource Conservation

Modular construction is rapidly gaining traction as a sustainable alternative to traditional building methods. One of the key benefits is the significant efficiency it offers. According to a report by the Modular Building Institute, modular construction can reduce construction time by 30-50% compared to conventional methods. This efficiency is largely due to the simultaneous execution of site preparation and module fabrication, which accelerates overall project timelines. As a result, projects can be completed not only faster but also with a notable reduction in labor costs and disruptions often associated with traditional construction methods.

Resource conservation is another crucial advantage of modular construction. The National Institute of Building Sciences highlights that modular construction can reduce waste by as much as 90%, primarily through precise manufacturing processes and controlled environments. The ability to create modules in a factory setting allows for better management of materials and minimizes the excess that is common on traditional job sites. Additionally, modular buildings are often designed for disassembly, making it easier to reuse materials and further enhancing their sustainability profile. Overall, these factors underscore the potential of modular construction to lead the way in eco-friendly building practices.

Environmental Impact: Reducing Carbon Footprint with Modular Design

Modular buildings represent a significant advancement in sustainable construction, primarily due to their potential to reduce the carbon footprint associated with traditional building methods. By utilizing pre-fabricated sections that are manufactured off-site, modular construction minimizes waste generated during the building process. This controlled environment allows for efficient use of materials, resulting in less waste sent to landfills compared to conventional construction techniques. As each module is produced with precision, quality is enhanced, and the need for excessive resource extraction is diminished.

Additionally, the transportation of these pre-fabricated modules often requires fewer trips than hauling raw materials to a construction site, further decreasing greenhouse gas emissions. Once assembled on-site, modular buildings are designed for energy efficiency, with features such as enhanced insulation and optimized layouts that reduce energy consumption. The speed of construction not only shortens project timelines but also lessens the impact of construction disruptions on the environment. Overall, modular design emerges as a forward-thinking solution that aligns operational efficiency with ecological responsibility, paving the way for a sustainable future in the construction industry.

Cost-Effectiveness: Financial Advantages of Modular Building Solutions

Modular buildings offer a compelling financial advantage in the realm of construction, fundamentally reshaping how projects are approached in terms of budgeting and overall cost management. The integration of prefabricated modules reduces the amount of time spent on-site, leading to significant labor cost savings. With sections of the building manufactured in a controlled factory environment and subsequently assembled on-site, projects can be completed more swiftly compared to traditional construction methods. This efficiency not only accelerates project timelines but also diminishes the costs associated with extended labor and potential delays.

Moreover, modular construction allows for precise budgeting due to its streamlined process. By employing standardized components and reducing wastage of materials, projects often come in under budget. This predictability enhances financial planning for developers and investors, presenting a less risky investment avenue. Additionally, the environmental benefits of modular buildings can lead to long-term cost savings related to energy efficiency and reduced operational costs, further underlining their appeal as economically viable construction solutions. Ultimately, the combination of quicker completion times and resource-efficient practices makes modular buildings an attractive option for those seeking both sustainability and financial prudence in construction.

Cost-Effectiveness of Modular Building Solutions

Future Innovations: Technology Advancements Driving Modular Construction Forward

The rise of modular buildings in the realm of sustainable construction is largely driven by significant technological advancements. According to a report by the Modular Building Institute, the modular construction industry has seen a 70% growth in the past decade. Innovations such as 3D printing, advanced prefabrication techniques, and smart building technologies have revolutionized the way structures are designed and constructed. 3D printing, for example, allows for more intricate designs with reduced material waste, enabling builders to create eco-friendly, customized solutions that meet diverse client needs while minimizing environmental impact.

Furthermore, the integration of Building Information Modeling (BIM) has transformed project management and collaboration in modular construction. A study from McKinsey shows that projects using BIM experience up to 38% fewer errors, leading to reduced construction time and cost. Additionally, modular buildings can often be assembled in a fraction of the time required for traditional construction methods, reducing the overall carbon footprint associated with longer project timelines. As technologies like IoT and AI continue to evolve, they are expected to further enhance the efficiency and sustainability of modular construction, paving the way for a greener future in the building industry.

Related Posts

-

10 Best Manufactured Buildings: Top Choices for Affordable Housing Solutions

-

Why Modular Interior Offices Are the Future of Workplace Design

-

Top Benefits of Modular Retail Buildings: Cost-Effective and Flexible Solutions

-

How to Create Functional and Stylish Modular Interior Offices for Your Workspace