Ramtech Building Systems is a leading provider of modular building systems including relocatable, permanent and prefabricated constructions.

T (817) 473-9376

Email: sale@viennavahouses.com

Ramtech Bulding Systems

1400 US Hwy 287 South Mansfield, TX 76063

Ramtech Blog

How to Choose the Right Prefabricated Building for Your Project

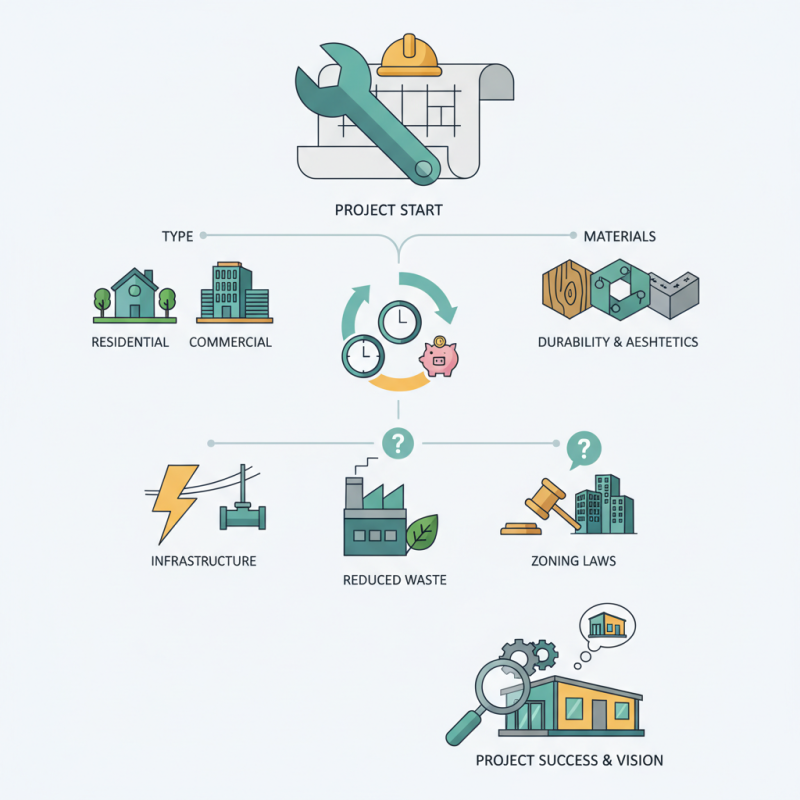

Choosing the right prefabricated building is crucial for your project’s success. This decision can significantly affect time, cost, and quality. Prefabricated buildings offer unique advantages, such as quicker assembly and reduced waste. However, they also come with their own set of challenges that require careful consideration.

When evaluating prefabricated buildings, think about your specific needs. What is the intended use? Will it be for residential or commercial purposes? The choice of materials can also impact durability and aesthetics. Different designs may suit different environments, yet aesthetics should not overshadow practicality.

It’s easy to focus on the positives and overlook potential downsides. For instance, does your site have the necessary infrastructure? Could zoning laws complicate your plans? Reflecting on these questions is essential. Understanding your project's nuances will lead you to the prefabricated building that truly fits your vision.

Understanding Prefabricated Building Types and Their Applications

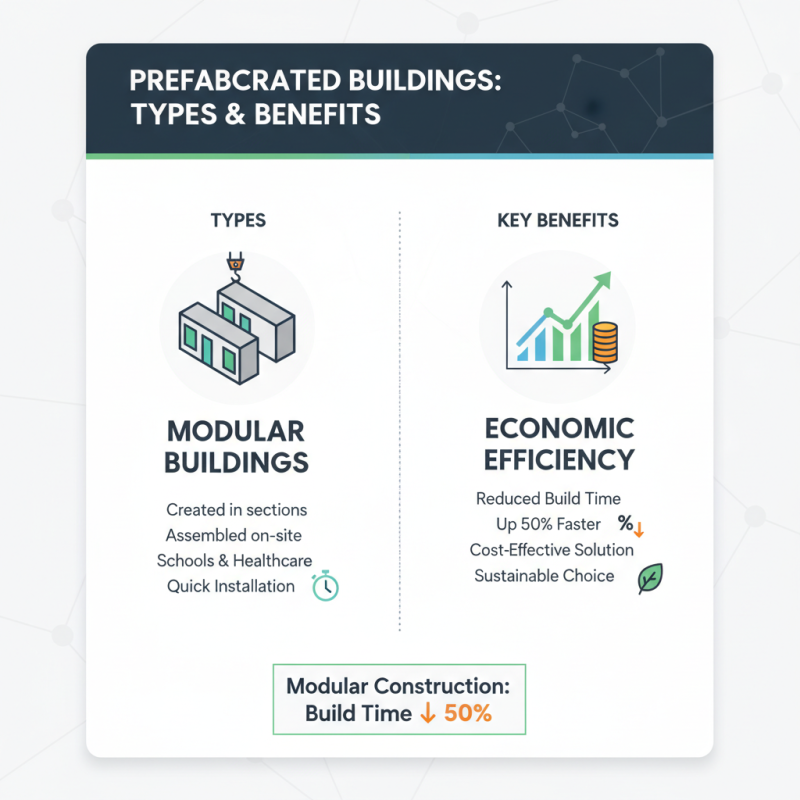

Prefabricated buildings come in various types, each serving unique needs and applications. Modular buildings, for instance, are created in sections and can be assembled on-site. They are often used for schools and healthcare facilities due to their quick installation time. Research shows that modular construction can reduce build time by up to 50%. Economic efficiency is a significant factor in choosing them.

Another type is panelized buildings, which are made of pre-made panels that are put together on-site. They offer great design flexibility, suitable for residential homes and light commercial buildings. The National Institute of Standards and Technology reports that panelization can help reduce waste by nearly 30%. However, careful consideration is needed. Poor planning or site selection can lead to inefficiencies. It's crucial to assess site conditions thoroughly.

Finally, shipping container structures are gaining popularity. They are cost-effective and eco-friendly, often repurposed from old containers. A recent study highlighted that they could be up to 70% cheaper than traditional buildings. Yet, not addressing insulation and weatherproofing can undermine their benefits. Understanding these nuances in building types helps ensure the right choice aligns with project goals.

Assessing Project Requirements: Size, Budget, and Timeline Considerations

Choosing the right prefabricated building starts with assessing your project requirements. Size is a critical factor. Consider the space needed for your operations. Will it accommodate future expansion? For instance, a small office may require a different layout than a workshop.

Budget is another vital consideration. A limited budget might restrict your options. It’s essential to factor in all costs—materials, transport, and labor. Sometimes, cheaper options may lead to higher long-term costs due to maintenance. Think about long-term needs as well. Will the building serve its purpose in a few years?

Lastly, timeline matters. Prefabricated buildings often promise quick installation. But unexpected delays can arise. Assess your deadlines realistically. Can you afford to wait? Sometimes, rushing can lead to compromises on quality. Ensure you’re prepared for any surprises.

Evaluating Material Options: Durability, Sustainability, and Cost Analysis

Choosing the right prefabricated building involves careful consideration of material options. Durability is a key factor. For instance, steel and engineered wood tend to outperform traditional materials in lifespan and resistance to environmental stressors. Reports show that steel structures can last over 50 years, while wood can also offer remarkable durability when properly treated.

Cost analysis is another critical aspect. The initial expense of prefabricated materials can fluctuate. Generally, prefabricated buildings save on labor costs and construction time. A recent study indicates that using prefabricated components can reduce construction duration by up to 50%. However, it's important to evaluate long-term costs, as cheaper materials may lead to higher maintenance bills.

Tip: Always compare material lifecycles. Investing in materials that require less maintenance can yield savings. Sustainability is more than a buzzword. It's essential to consider energy-efficient materials. Options like recycled steel not only reduce waste but also lower energy consumption.

Tip: Don't overlook local climate. Materials must withstand specific weather conditions. Sometimes, cheap materials fade or become damaged quickly due to environmental factors. Reflect on this: balancing cost and durability can lead to better choices for your project. Remember, the ideal material should perform well and fit within your budget.

Regulatory Compliance: Navigating Building Codes and Permits

Navigating building codes and permits can be overwhelming. Each region has specific regulations. Ignoring them can lead to delays and fines. It’s essential to address compliance early in your project.

Tip: Start with local zoning laws. Check if your site is appropriate for a prefabricated building. Understanding land use regulations is crucial. If you find discrepancies, consider alternatives.

Review required permits next. Some projects may need multiple approvals. Research which permits apply to your prefabricated building. This step might seem tedious, but it’s necessary. Skipping it can halt your project entirely.

Tip: Consult local authorities or a construction expert. Their guidance can streamline the process. They might point out key details you overlooked. Building codes evolve, and staying updated is vital.

Regulatory Compliance: Building Codes Compliance by Project Type

Selecting Reliable Manufacturers: Key Criteria and Industry Best Practices

Choosing the right prefabricated building is crucial for a successful project. Selecting a reliable manufacturer is one of the primary steps. Industry reports show that over 60% of project delays stem from poor supplier relationships. To avoid these pitfalls, focus on key criteria when making your selection.

Look for manufacturers with a strong track record. A manufacturer should have been in business for at least five years. This experience often correlates with reliability. Additionally, assess their previous projects. Did they deliver on time? Were clients satisfied? Reviews are invaluable in this process.

Tip: Create a checklist of qualities you need. These could include certifications, material quality, and flexibility in design. Regularly revisit and update this list.

Make sure to review the manufacturer's compliance with industry standards. Many builders might not meet local building codes, which can lead to costly reworks. Technology plays a role too. Manufacturers using advanced designs and sustainable materials are often more efficient.

Tip: Schedule visits to their facilities if possible. Direct observations can highlight strengths and weaknesses that reports might not reveal. Seek transparency in communication. A manufacturer that is open about processes and challenges is often more trustworthy.

Related Posts

-

Top Benefits of Modular Retail Buildings: Cost-Effective and Flexible Solutions

-

Why Modular Interior Offices Are the Future of Workplace Design

-

Why Modular Buildings Are the Future of Sustainable Construction Solutions

-

What is a Prefab Business Building and Why Choose This Construction Method

-

10 Best Manufactured Buildings: Top Choices for Affordable Housing Solutions

-

Top Benefits of Used Modular Office Buildings for 2025 Workspaces